Electric Vehicles

Jump to:

Benefits of Electric Vehicles (including electric buses)

The Drive System

Electric Motor Comparison

Motor Characteristics

Control Systems

Battery Systems

How Does a Cell Work?

Performance of Vehicle Battery Systems

Battery Memory

Types of Charging

Charger Location/Coupling Options

Charging Methods

Charge Levels

Battery Management

Accessories (Power windows, heating, air, power steering, etc.)

There are many benefits of operating electric vehicles. First, there is no fuel odor as the vehicles operate on batteries, not on gasoline, diesel, or some other type of combustible fuel. Electric vehicles are quiet...the ride is virtually silent. By correctly using regenerative braking, electric vehicles achieve greater brake life as well as create energy through kinetic energy. By using high-tech composite technology, electric vehicles can be much lighter than an ICE counterpart which also helps reduce brake wear along with road wear.

Electric vehicles are much more energy efficient. Electric motors convert virtually all of their fuel energy into usable power. The internal combustion engine (ICE) is less than 20% efficient.

Maintenance cost, including fuel cost, is much lower with an electric vehicle. There are no tune ups or oil changes necessary. By eliminating everything on a vehicle maintenance checklist that pertains to the ICE, it becomes a pretty short list. And, by charging at night, the "fuel" for an electric vehicles is reduced up to one-fourth the cost of gasoline or diesel.

Electric vehicles, especially electric buses, provide great public relations benefits. The public and media alike love riding in and talking about zero-emission electric vehicles.

There are, however, two primary benefits of electric and hybrid-electric vehicles. Electric and hybrid-electric vehicles can help reduce our nation's use of foreign oil, and reduce pollution that negatively impacts health and well-being.

An electric vehicle is a motor vehicle, such as an automobile, truck, or bus, that uses a rechargeable battery for fuel, replacing gasoline, diesel or other types of combustible fuels. Gone is the internal combustion engine and the transmission. An EV utilizes an electric motor or, in some applications, more than one motor to propel the vehicle.

Electric vehicles are similar in many aspects to vehicles powered with internal combustion engines. The chassis or body of many electric vehicles on the road today are from vehicles that once contained an internal combustion engine (ICE). In most electric vehicles, even the interior of the vehicle is unchanged and almost all electric vehicles contain the same accessories as their internal combustion cousins.

The energy stored in the Electric Vehicle's rechargeable battery supplies power to the motor controller. The motor controller is a device, which controls the amount of power supplied to the electric drive motor(s) based on the position of the accelerator pedal. The electrical power supplied to the electric drive motor(s) is used to generate an electromotive force, which turns the shaft of the electric motor(s). This shaft is coupled to the wheels of the vehicle and causes movement either forward or reverse, depending on the direction the shaft is turning.

Refueling an electric vehicle consists of plugging in the vehicle's charge plug into an outlet that is specifically designed for charging an electric vehicle. Recharging time varies, depending on the battery type, capacity and the voltage/current output of the charger. Most EV's can be recharged in about 6 hours.

The primary focus of EV's is to reduce the amount of noxious gases that are released into the air due to the combustion process of an internal combustion engine. An electric vehicle produces zero emissions. Some critics of the EV industry will argue that a reduction of polluting gases has not taken place because of the emissions that are generated in the production of electricity at the power plants. Though it is true that power plants do produce some pollutants, the government has very strict regulations on power plant emissions. And since power plants produce an excess of power at night, when the demand is low, EV owners can use the excess power by recharging at night. This makes the power plants more efficient.

Additionally, electric vehicles are much more energy efficient then ICE vehicles. Not only is the propulsion system itself much more efficient, but energy loses through the transmission and idling simply do not exist. Because there is no transmission, acceleration is "seamless"; no jerking or noise....just nice and smooth.

Benefits of Electric Vehicles (including electric buses)

An electric vehicle has many advantages over vehicles utilizing an internal combustion engine. An electric vehicle is very clean. There are no gaseous emissions. Also eliminated are other problem pollutants such as oil, transmission fluid and radiator fluid. In some EV's, the only hydrocarbon based substance used is the grease which lubricates bearings.

Electric vehicles are very simplistic. The propulsion system in an ICE vehicle has hundreds of moving parts. An electric vehicle's propulsion system has but one: the electric motor. In addition to reducing maintenance costs and saving on lubricants and oils, the reduction in friction losses contributes to the energy efficiency of electric vehicles.

Electric vehicles are very energy efficient. For every 100 units of fuel that are expended in an ICE vehicle, only 16 actually result in propulsion. An electric vehicle, however, will use almost 85 units out of 100 for driving the vehicle.

Electric vehicles have another significant advantage over ICE vehicles: regenerative braking. When an electric vehicle is slowing down, the motor becomes a generator and provides energy to the batteries. An additional benefit of this process is the braking effect of the motor on the vehicle, thereby reducing brake wear.

An electric vehicle is very quiet. The problem for engineers designing these vehicles becomes one not of muffling the motor but rather trying to quiet the noise of other systems such as the air conditioning, power steering or air compressors.

Most electric vehicles do not utilize a transmission. The motors are usually single speed and acceleration is smooth, no bump or jolt like transmissions in today's vehicles.

An electric vehicle can be recharged at home, saving a stop at a gas station. The only downside to this is the time it takes to fully recharge an "empty" battery. In some cases this could be as long as 6 hours. Charger technology is rapidly improving and it is currently possible to recharge an "empty" battery to 80% full as quickly as 20 minutes.

The main obstacle facing electric vehicles today is the energy storage capability of batteries. The capacity of the battery limits the range that the vehicle can travel. Many different types of batteries are being tested for use in electric vehicles. These include lead-acid, nickel-cadmium, nickel iron, nickel zinc, nickel metal hydride, sodium nickel chloride, zinc bromine, sodium sulfur, lithium, zinc air and aluminum air. These advanced batteries, although much more expensive, will in time enable an electric vehicle to achieve the same range that today's fossil fueled vehicles can travel.

The Drive System

An Electric Vehicle's drive system performs the same functions as that of a vehicle powered by an internal combustion engine. The drive system is that part of the EV which transmits mechanical energy to the traction wheels causing the EV to move. The components used in an EV are very different from a standard vehicle. In an EV, a transmission is not necessary. A transmission in a standard vehicle is used to give the vehicle a certain torque or power at certain speeds by changing the gear input/output ratio within the transmission. The change in gear ratio is governed by the speed(RPM) that the vehicle's power plant, or engine, is turning. Because there is a mechanical shift from one set of gears to another, a jolt is usually felt by passengers as speed is increased or decreased and the transmission shifts to larger or smaller gears.

EV's utilize an electric motor to turn the wheels of the vehicles. There are several different drive system designs in use today. These include vehicles with a single large electric motor coupled to the rear wheels through a differential housing. Other designs utilize two smaller motors to power each wheel separately through independent drive shafts.

The most efficient design to date utilizes motors which are attached directly to the wheel. These are referred to as "wheel motors". By eliminating driveshafts and differentials, mechanical losses between the motor and wheels are kept at a minimum. The power system of an electric vehicle includes both the drive system and control system. The controller delivers power to the motor from the batteries. The motor in turn delivers power to move the vehicle to the drive wheels through a gearbox..

Electric motors convert electrical energy into mechanical energy. Two types of electric motors are used in electric vehicles to provide power to the wheels. The direct current(DC) motor and the alternating current(AC) motor. DC motors are comprised of three main components:

- A set of field coils around the perimeter of the motor that creates the magnetic forces

- which provide torque.

- A rotor or armature mounted on bearings that turns inside the magnetic field created by the field coils.

- A commutating device that reverses the magnetic forces and makes the armature turn, producing the mechanical force used to turn the drive wheels.

An AC motor is similar to the DC motor in that it also has a set of field coils and a rotor or armature, however since there is a continuous current reversal (alternating current), a commutating device is not needed. At this point in development, neither motor can be considered superior to the other. They both have advantages and disadvantages as listed below.

Electric Motor Comparison

AC Motor | DC Motor |

Single-speed transmission | Multi-speed transmission |

Light weight | Heavier at equivalent power |

Less expensive | More expensive |

95% Efficiency at full load | 85-95% Efficiency at full load |

More expensive controller | Simple controller |

Motor/controller/inverter more expensive | Motor/controller less expensive |

As shown in the comparison, an AC motor is less expensive than a DC motor, an AC system is more expensive due to the cost of the complex electronics associated with the AC inverter and motor controller. AC motors are the most commonly used motor in home appliances and machine tools. These motors are very reliable and because they contain a single moving part, they should last the life of the vehicle with little or no maintenance. Typical motor characteristics are listed in the table below.

Motor Characteristics

DC Brush Type | Brushless DC Permanent Magnet | AC Induction | |

Peak efficiency | 85-89 | 95-97 | 94-95 |

Efficiency at 10% Load | 80-87 | 73-82 | 93-94 |

Max. RPM | 4,000-6,000 | 4,000-10,000 | 9,000-15,000 |

Cost per shaft Hp | $100-150 | $100-130 | $50-75 |

Relative Cost of Controller to DC Brush Type | 1 | 3-5 | 6-8 |

1 Hp = 746 Watts |

The electric vehicle controller is the device which operates between the batteries and the motor to control speed and acceleration. The controller transforms the battery's DC current into alternating current for the AC motors or simply regulates current flow for DC motors. The controller can also reverse the field coils of the motor so that when in a braking mode, the motor becomes a generator and energy is put back into the batteries. This is known as regenerative braking and over the course of a single charge can return as high as 10% or more of the energy consumed by the drive system to the batteries.

One of the well publicized benefits of an EV is regenerative braking. Regen braking is common on nearly all vehicles now, yet few people seem to realize what happens. The following paragraph is an attempt to explain how it works.

In the circuit shown above is an output pair of MOSFETs Metal Oxide Semiconducting Field Effect Transistors), with the motor being driven. The output from the controller is a pure d.c. voltage. The motor will generate a back e.m.f. which is proportional to its speed of rotation. At zero load, or no acceleration, this back e.m.f. will rise to be equal to the output from the controller.

The MOSFET is a bi-directional switch which conducts resistively (when it is turned on) for both directions of current. So consider the situation when the current is zero and the controller's output is now reduced. The motor's back e.m.f. is now higher than the controller's output voltage - so the motor will try and feed current back into the controller. If it succeeds in so doing the motor will be braked - we will have regenerative braking.

This type of circuit (where hi-side is turned on when the low-side is off) is capable of sourcing current or sinking it. The way this works is that the reversed motor current is now a forward current to the flywheel MOSFET so when this is on it shorts out the motor - whose braking current rises during this period (arrow B, reversed). The Flywheel MOSFET now turns off, but this current must keep flowing - because of the motor's inductance. So it flows as reverse current through the drive MOSFET, recharging the battery as is does so. The extra voltage for this is derived from the energy stored in the motor's inductance. The process of switching from drive to braking is entirely automatic. Moreover it is done entirely by the motor's speed exceeding the drive voltage and without any change of state or switching within the controller. The regen braking is, if you like, a by-product of the design of the controller and almost a complete accident.

If the vehicle is driven down too steep a hill (or the demand speed is suddenly reduced so that very hard braking results) the current generated by the motor could exceed that which the MOSFETs can safely handle. Since this would blow the MOSFETs it must be protected against so all controllers that give regenerative braking are also fitted with a current limit to stop such failure.

In Hybrid Electric Vehicles this problem becomes even more complex because of the unused current from the auxiliary power source. Since the drive motors are not drawing current from the auxiliary power source, that current still must have some place to go. The motor controller should monitor and take into account the excess current from the auxiliary power source, so that in certain situations where too much current is present with regen and APU operating, the regen MOSFET must also be turned off. to protect the motor controller.

In early version of electric vehicles with DC motors, a simple variable resistor type controller governed the acceleration and speed of the vehicle. Full current and power was drawn from the battery all of the time. At lower speeds, when little power was needed, high resistance was used to reduce the current to the motor. This resulted in a large percentage of the battery's energy being wasted as heat dissipated by the resistor. Modern controllers adjust speed and acceleration by and electronic process called pulse width modulation(PWM). Switching devices such as IGBT's(very fast, high current rated transistors) rapidly interrupt, turning on or off as needed, the flow of electricity to the motors. High power is achieved when the intervals(time between pulses) are very short. By increasing the time between pulses, the current is limited.

As mentioned above, one of the more interesting designs for motors is to integrate the motor directly into the wheel. These are called wheel motors and may very well become the norm someday as they remove a tremendous amount of mechanical devices from the vehicle by providing propulsion to the wheel...in the wheel!

The motor-wheel assembly is an elegant integration of an electric motor and other components into a package that fits inside a regular-size tire.

The motor-wheel assembly consists of a highly efficient electric motor, a Motor-Wheel Slave Controller (MWSC) including power and control electronics, a brake, wheel bearings, a steerable front suspension interface and a heat sink embedded in the stator. The configuration of the 3-phase synchronous motor consists of a central stator which supports the windings and the inverter, surrounded by an external rotor which supports the permanent magnets.

The wheel is directly mounted on the rotor for direct transmission of torque and enhanced freewheeling. The motor assembly is liquid-cooled to sustain high continuous power demands.

Bus manufacturers will appreciate the packaging advantages and interchangeability of the motor-wheel rear axle, which easily fits within existing wheel housings. The axle deep-offset cross member enables a wider floor aisle area in the low-floor configuration.

Selecting a motor for use in an EV involves many variables. No single type of motor can be considered as the best. When an EV is being designed, questioned must be answered before selecting a specific type of motor. How much power do you need, do you need variable speeds, what is the operating voltage of the battery system, what kind of torque do you need and at what speed, how much physical space can the motor occupy, how much can it cost, what type of environment will the motor be operating in? Once these questions are answer, you can make your motor selection. Once the motor has been identified, a control system must be designed to make the motor functional.

Control Systems

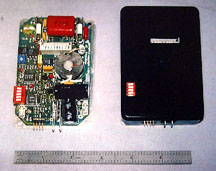

The most complex and important system in an EV is the control system. The control system is responsible for governing the operation of the electric vehicle. The control system receives inputs from the operator, Controller feedback signals from the motor controller and motor and also feedback signals from other systems within the EV. The speed at which the control system must receive data from other systems, process the data in an algorithm and output a response to the given conditions must be accomplished in milliseconds. This requires the control system to have a microprocessor, just like a computer, to accomplish its tasks. Though no two control systems are identical, most of the feedback signals are similar. The table below lists common components of a control system and the feedback signals that are sent to the microprocessor. | |||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||

The control system must continuously monitor the feedback signals listed above. For instance, if the temperature of the windings in the motor gets too hot, the magnetic properties of that motor can be permanently altered or the windings may melt. By feeding a signal back to the microprocessor, the control system can limit the output of the motor if it senses a temperature rise. The same limiting or shutdown of any system can take place if an undesirable condition is or has occurred. Other feedback signals give information to the microprocessor to control the speed of the vehicle. The accelerator pedal functions in much the same way as conventional vehicles. As the pedal is depressed, an increasing signal voltage(not traction battery voltage) is sent to the microprocessor which instructs the motor controller to increase the amount of current in the motor windings, causing the motor to spin faster. As the signal voltage from the accelerator pedal is decreased, the motor spins slower.

In some advanced control systems, it is possible to limit the amount of current that flows to the motor, based on a switch selection. This allows the operator to adjust to a driving style that fits a particular situation. For instance, if a driver needs a certain range(in miles) from a single charge, the range selection can be set so that the microprocessor will limit the amount of output current from the motor controllers to a preset limit. If the preset limit is 100 amps, the microprocessor will not allow any current above this limit to flow to the motors. In this mode, acceleration ability is sacrificed for range. If the driver is in an area where the vehicle must climb steep grades, the range selector can be set so that the maximum current capability of the motor controller and motor can be used. The range selection feature is a valuable feature that adds to the efficiency of the motor controller. The ultimate goal of a control system is to maximize the energy stored within the traction battery and to prevent unsafe conditions from occurring within the electric vehicle.

Battery Systems

An electric vehicle's battery defines the range, acceleration ability and recharge time for the vehicle. Because the battery contains the energy to fuel an electric vehicle, and because today's batteries do not provide electric vehicles with the same range potential as ICE vehicles, batteries, and alternative options such as flywheels and ultra capacitors, are the most heavily studied areas in electric Battery cell vehicle technology. | |||

A battery cell normally consists of the 4 principal components shown at the left. A cell contains a positive and negative electrode, electrolyte, and a separator. The positive electrode receives electrons from the external circuit when the cell is discharged. The negative electrode donates electrons to the external circuit as the cell discharges. The electrolyte provides a mechanism for charge to flow between positive and negative electrodes. The separator electrically isolates the positive and negative electrodes. | |||

How Does a Cell Work?

When a battery or cell is inserted into a circuit, it completes a loop which allows charge to flow uniformly around the circuit. In the external part of the circuit, the charge flow is electrons resulting in electrical current. Within the cell, the charge flows in the form of ions, that are transported from one electrode to the other. The flow is due to reduction and oxidation reactions that occur at each electrode. For every electron generated in an oxidation reaction at the negative electrode, there is an electron consumed in a reduction reaction at the positive electrode. The discharge reaction at the positive electrode, which has a potential of 1.685 volts, is given by:

The reaction at the negative electrode, which has a potential of .356 volts, is given by:

|

This means that the overall voltage of a lead-acid cell is 2.04 volts. This value is known as the standard electrode potential. Other factors, such as acid concentration can also affect the voltage of a lead-acid cell. The typical open circuit voltage(no load condition) is around 2.15 volts.

While the voltage of a cell is fixed by its chemistry, cell capacity is variable depending on the quantity of active materials it contains. Individual cells may range from fractions of an ampere-hour to thousands of ampere-hours. The capacity of a cell is essentially the number of electrons that can be obtained from it. Since current is the number of electrons per unit time, cell capacity is the current supplied by a cell over time and is given in ampere-hours.

EV applications require a tremendous amount of energy. The traction battery on electric vehicles consists of many cells that are connected electrically to meet the necessary energy storage capacity. Batteries can be wired together in a series configuration or a parallel configuration.

In a series configuration, the negative terminal of one battery is connected to the positive terminal of the next and so on until the desired voltage and energy capacity of the battery are met. The total pack voltage is can be found by multiplying the number of batteries in the circuit by the individual cell voltage.

In a parallel configuration, the positive on one battery is connected to the positive on the next and the same goes for the negative terminal. In this case, you can reach your desired energy storage Parallel battery capacity, but the total pack voltage is equal to the voltage of the individual cell. The battery system consists of more than just a battery. There are a host of other components within this system that monitor every pertinent variable about the battery and recharging method.

The battery system consists of more than just a battery. There are a host of other components within this system that monitor every pertinent variable about the battery and recharging method.

Many different battery types are in use in electric vehicles today. The most common batteries in use today are flooded lead-acid, sealed gel lead-acid, Nickel Cadmium (Ni Cad) and Nickel Metal Hydride (NiMH).Battery types, sizes and configurations cover a wide variety of options. When an EV manufacturer is in the design process, several questions must be answered before the battery selection is made. This would include questions such as how much space is available for the batteries, how much can they weigh, what is the desired range, what is the weight of the vehicle, what is the targeted vehicle cost, how will the batteries be recharged and what kind of drive system requirements are needed. These are necessary questions because of the variety of battery types available and the differences between them. The chart below lists the characteristics of the most common types of batteries.

Performance of Vehicle Battery Systems

Each specific type of battery has characteristics which make it either more or less desirable to use in a specific application. Cost is always a major factor and the NiMH battery tops the list in price with flooded lead acid batteries being the most inexpensive. What is lost in the cost translation is the fact that NiMH batteries yield nearly twice the performance (energy density per weight of the battery) than do conventional lead acid batteries. Another factor that must be considered when making a battery comparison is the recharge time. Lead acid batteries require a very long recharge period, as long as 6 to 8 hours. Lead acid batteries, because of their chemical makeup, cannot sustain high current or voltage continuously during charge. The lead plates within the batteries heat rapidly and cool very slowly. Too much heat results in a condition known as "gassing" where hydrogen gas is released from the battery's vent cap. Over time, gassing reduces the effectiveness of the battery and also increases the need for battery maintenance. Batteries such as NiCad and NiMH are not as susceptible to heat and can be recharged very quickly, allowing for high current or high voltage charges which can bring the battery from a 20% state of charge to an 80% state of charge in as quick as 20 minutes.

Battery Type | Energy Density Whr/kg | Power Density W/kg | Life Cycles Per Battery | Cost on scale of 1 to 10 |

Current Lead Acid | 35 | 150 | 500 | 1 |

Advanced Lead Acid | 48 | 150 | 800 | 3 |

GM Ovonic NiMH | 70 | 220 | >600 | 8 |

SAFT NiMH | 70 | 150 | 1,500 | 8 |

SAFT lithium ion | 120 | 230 | 600 | 9 |

Lithium polymer | 150 | 350 | <600 | 10 |

Zebra sodium-nickel chloride | 86 | 150 | <1000 | 4 |

Impact on Vehicle performance | Range | Acceleration | Life Cycle Cost, Replacement Cost | Initial Cost, Replacement Cost |

The overall battery pack voltage varies from one vehicle to another. Discussions are currently in progress with EV manufacturers in an attempt to standardize a vehicle's nominal battery voltage. EV visionaries hope to have vehicle recharging stations available in parking lots throughout a city. If EV's have a set battery pack voltage range, all vehicles would be able to use the same chargers. Battery charger manufacturers are currently developing "smart" chargers that are microprocessor based. The "smart" charger would access the particular vehicle's data bank, and be able to regulate the charge accordingly.

New technology battery systems are also driven by a microprocessor. The microprocessor receives data from sensors within the battery pack. Temperature, current output, battery voltage and fault detection are all fed back to the microprocessor which can then calculate how much energy is remaining in the battery as well as how much has been consumed. Monitoring the temperature and the resistance to the vehicle's ground protects both the battery pack and the passengers from danger.

Battery configurations also vary greatly depending on the vehicle and the desired redundancy of the system. Battery packs can be tied together in one long series circuit so that the total pack voltage is the sum of all the cells in the series. Other systems use multiple packs that are of equal voltage and parallel the multiple packs. This provides redundancy to the system. If a cell goes bad in a single pack, the battery management system can disable the output from that pack and the vehicle can continue to be driven off of the remaining battery packs. The vehicle will lose the energy from the faulty pack and range will be affected.

Shown to the left is a battery pack consisting of 27 individual 2 volt cells, in a series circuit configuration to form a pack with a voltage of 54 volts. |

Factors that influence battery selection for specific applications:

For pure electric vehicles, battery selection is a primarily a function of energy density. Energy density is defined as the amount of energy stored in a cell or battery as a function of the weight or volume. The ideal battery would therefore be the battery that yields the most energy, occupies the smallest space and weighs the least(disregarding cost). The most promising battery technologies available today are Lead-Acid(Pb-acid), nickel cadmium(NiCd), nickel metal hydride(NiMH), lithium polymer and lithium ion batteries. A comparison of energy densities is shown in the chart above. There are many factors besides energy density that influence the type of battery selected for use in an electric vehicle. These include cost, cycle life(the number of charge-discharge cycles before the capacity diminishes from the original 100% to 80%), fast or rapid charge time and specific power(the maximum load current the battery can provide for a very short duration). Another criteria for selecting a battery type that is closely related to energy density is a battery's specific energy.

Specific energy is energy density as a function of time measured in watt-hours per unit mass. Specific energy is important because it affects the number of batteries necessary in a particular application, and in turn the mass or weight of the batteries that a vehicle needs to carry on-board to end up with a certain electric-only range. It is the most important factor for EVs because it determines their total range, but not as critical for HEVs which carry the majority of their energy in the form of a gaseous or liquid fuel. Instead, for HEVs, a battery's specific power becomes the critical parameter in selecting a battery.

Since HEVs utilize two different energy sources, energy demands from the batteries are much less than in EVs. Because hybrids normally only depend on the electrical energy stored on-board to provide power for acceleration and hill climbing, batteries are sought that have a high specific power rating and less mass. Specific power, is power per unit mass, so the ability of the battery to enable high current draws for short durations with less weight is the desired goal for HEVs. Shown at right is a chart which compares specific power between battery types. No information was available for the lithium batteries at this time.

Battery chargers replenish the energy used by an electric vehicle much like a gasoline pump refills a gas tank. One significant difference is that an electric vehicle operator can fully charge the vehicle overnight, at home, rather than refueling at a gasoline station. The battery charger is a device which converts the alternating current distributed by electric utilities to the direct current needed to recharge the battery.

Battery Memory

It is often heard that batteries have memory. When "memory" is talked about in the same sentence with batteries, it means a battery has failed to produce it's stated capacity. If a battery has a stated capacity of 100 amp-hours, and the cutoff voltage is consistently reached when only 80% or 80 amp-hours has been consumed after having been charged it is often referred to as the memory effect. There are many opinions as to whether or not batteries have memory. The use of the term "memory" to describe the loss of capacity is likely the source of the confusion. A battery's performance can be consistently poor, having a discharge capacity within 2% to 3% during each discharge cycle. But batteries do not get that way from "memory". They are several different causes of this poor performance, and generally it is the battery's caretaker who is responsible for this effect.

Some of the more common causes of performance problems that are attributed to the "memory" effect are;

1. Improper charging, i.e., consistently overcharging or undercharging

2. Exceeding battery temperature thresholds during charging or discharging

So what has happened to the battery that is experiencing a "memory" effect? Because of the different types of batteries and chemicals involved, there is no single generic term that can be applied that describes what causes the poor performance in all batteries. However, what is known is that high temperatures alter the molecular structures of the chemicals involved, which can lead to a higher internal resistance within the battery which leads to voltage depression. Undercharging can lead to a buildup of lead sulfate on the plates of lead-acid batteries which also increases the internal resistance of the battery because currents become constricted and cannot flow through the full surface area of the plates. Overcharging can have the same effect that high temperature has, altering the crystal structures of the chemicals within the battery.

Can the battery's "memory" be erased? In most cases the answer is "yes". By proper execution of several charge/discharge cycles, the memory effect can be destroyed and the battery capacity will return to it's original value. In some cases, however, if a battery has been poorly maintained for an extended period of time(months), it is possible that permanent damage has occurred and the life and capacity of the battery is defined and cannot be corrected.

Types of Charging

There are a number of different types of battery chargers based on the way they control the charging rate.

Constant Voltage

A constant voltage is applied and the current flows into the battery (the highest current occurs when the battery has been fully discharged and steps down to a low current when the battery is nearly charged.) Electronics on constant voltage charges is relatively simple, therefore, these types of chargers tend to be less expensive.

Combination Constant Current/Constant Voltage

The charge cycle starts with a high constant current until the voltage reaches a set value, then changes to a constant voltage control. This is the most sophisticated of the basic types of battery chargers and generally increases the life of a battery by reducing heat during the charging process. These chargers also tend to increase battery performance.

Pulse Charging

One of the advanced charging methods currently being evaluated eliminates the practice of requiring constant current and/or constant voltage by "pulsing" voltage. A series of very high current and voltage pulses are applied until the battery voltage reaches a set value. The major advantage of a pulse charger is the significant reduction in heat which allows the charger to operate at a high voltage rate even when the battery is almost full. Additionally, the reduction in heat results in a reduction in "lost" energy. Thus, pulse charging can significantly reduce charging time and are more energy efficient.

While there are many types of battery chargers available, the vehicle manufacturer will supply or recommend the proper charger for the batteries in the electric vehicle.

Charger Location/Coupling Options

Electric vehicle battery chargers may be onboard (in the electric vehicle) or offboard (at a fixed location). As with many options, there are advantages and disadvantages with both types. If the battery charger is onboard, the batteries can be recharged anywhere there is an electric outlet. The drawback with onboard chargers is the limitation in their power output because of size and weight restrictions dictated by the vehicle design. Offboard charges are limited in their power output only by the ability of the batteries to accept the charge. While the EV owner can shorten the time it takes to recharge the batteries with a high-power, offboard charger, the flexibility to charge at different locations is restricted.

Charging Methods

There are two basic coupling methods used to complete the connection between the utility power grid, the battery charger, and the vehicle connector. The first is the traditional plug (called conductive coupling). With this connection, the EV operator plugs his vehicle into the appropriate outlet (i.e. 110 or 220 volts) to begin charging. This type of coupling can be used with the charger in the car (onboard) or out of the car (offboard).

The second type of coupling is called inductive coupling. This type of coupling uses a paddle which fits into a socket on the car. Rather than transferring the power by a direct wire connection, power is transferred by induction, which is a magnetic coupling between the windings of two separate coils, one in the paddle, the other mounted in the vehicle.

Inductive Charging

The inductive charger has no direct electrical connection to the vehicle. A weatherproof paddle transfers power to the vehicle’s charge port via magnetic field . The Delco off-vehicle chargers provides a safe and easy-to-use system for EV charging. Inserting the charge coupler is all that is required to initiate charging. Charging can be terminated at any time by removing the coupler. Bi-directional communication and built-in diagnostics ensure a safe connection and prevent the vehicle from being driven while connected.

Conductive Charging

With a conductive charger, energy is transferred to the vehicle via metal-to-metal contact. A connector, such as the AVCON (left), safely performs the link between a power supply and the vehicle’s charge port.

Charge Levels

Chargers are also classified by the level of power they can provide to the battery pack:

Level 1 - Common household type of circuit, rated to 120 volts/AC and rated to 15 amps.

Level one chargers use the standard household 3-prong connection and they are usually considered portable equipment.

Level 2 - Permanently wired electric vehicle supply equipment used specially for electric vehicle charging and it is rated up to 240 volts/AC, up to 60 amps, and up to 14.4 kilowatts.

Level 3 - Permanently wired electric vehicle supply equipment used specially for electric vehicle charging and it is rated greater than 14.4 kilowatts. Fast chargers are rated as Level 3 chargers. However, not all Level 3 chargers are considered as fast chargers. This depends on the size of the battery pack to be charged and how much time is required to charge the battery pack. A charger can be considered a fast charger if it is capable of charging an average electric vehicle battery pack in 30 minutes or less.

Battery Management

With so many differences in chargers and charging methods, there existed a need to monitor the status of the batteries being charged and discharged. Battery Management Systems (BMS) have been developed which are microprocessor controlled allowing charge algorithms to be programmed into the system for virtually all the different battery types. These systems monitor the energy consumed by the vehicle while being driven, as well as temperature, individual cell voltages and total pack voltage. The same process is monitored in reverse during charging creating a safety net in the event of problems with a single cell within the battery pack.

With existing electric vehicles and battery chargers, it usually takes from several hours to overnight to recharge an electric vehicle battery pack. The time required to recharge electric vehicle batteries depends on the total amount of energy that can be stored in the battery pack, and the voltage and current (i.e., power) available from the battery charger.

New developments in battery recharging decreases the time required to recharge electric vehicle batteries to as little as 10-15 minutes. For example, pulse battery chargers have demonstrated that the EV battery pack can be recharged in under 20 minutes without damaging it. When this technology is fully deployed, electric charging stations, similar to gas stations, will allow the electric vehicle operator to quickly recharge the battery pack.

This new charger technology, coupled with advanced batteries with a range of 200 miles between recharging, will allow the electric vehicle operator the same freedom of the road currently enjoyed by today's operators of gasoline-powered vehicles.

Accessories (Power windows, heating, air, power steering, etc.)

An EV maintains the same accessory functions as a vehicle utilizing an internal combustion engine. These accessories include radios, lights, heating and air conditioning, power steering, and for larger vehicles such as trucks and buses, an air system. However, the manner in which these devices obtain power is very different. A combustion engine is equipped with a generator for 12 volt power. The engine cooling system is the heat source for the vehicle. Air conditioning and power steering are accomplished using a belt and pulley system which interfaces with a pump for the power steering and a compressor for the air conditioning. Since electric vehicles do not utilize an engine, alternative methods have been developed to work with EVs.

The 12 volt accessory system which supplies power to devices such as lights, radio, windshield wiper and washer system, power windows and door locks or any other electrical device on the vehicle consumes energy from the main traction battery. The accessory system does not operate at the same voltage level as the traction system(the system that provides power to the wheels), but is instead stepped down from a voltage range of 324-216 volts DC to 12 volts DC though a device called a DC to DC converter.

There are several different methods that can be used to heat an electric vehicle. One of the first methods used was known as "resistance" heating. Resistance heating is accomplished using a heat element, similar to heat elements on a stove top or in the oven. The heat element is warmed when electricity is applied, and a fan blows across the element to disperse the heat. The disadvantages of this method included safety and efficiency. Heat elements consume a large amount of energy. Other alternative methods of heating included using heaters which burned a clean fuel such as liquid propane or compressed natural gas. Cooling electric vehicles has been accomplished in the past using standard air conditioning technology similar to window mount home air conditioners. These air conditioners were effective though inefficient. Recent developments in power electronics has enabled vehicle manufacturers to place an efficient reversible heat pump, one that can cool or heat, into electric vehicles.

Power steering on an electric vehicle is accomplished by adding a single speed DC motor and a motor controller. The motor is coupled to the power steering pump through gears or a belt and pulley system. The motor controller's job is to keep the motor spinning at a constant speed under varying loads. The air system on large trucks and buses utilizes this same methodology with the DC motor turning the shaft of an air compressor. What is important to realize here is that the DC motors will only come on and stay on if the vehicle needs air or power steering. If the vehicle is stopped, power steering is not needed and the power steering motor will shut off. Whenever the air tanks are full, that motor will also shut off.