Arman Raoufi

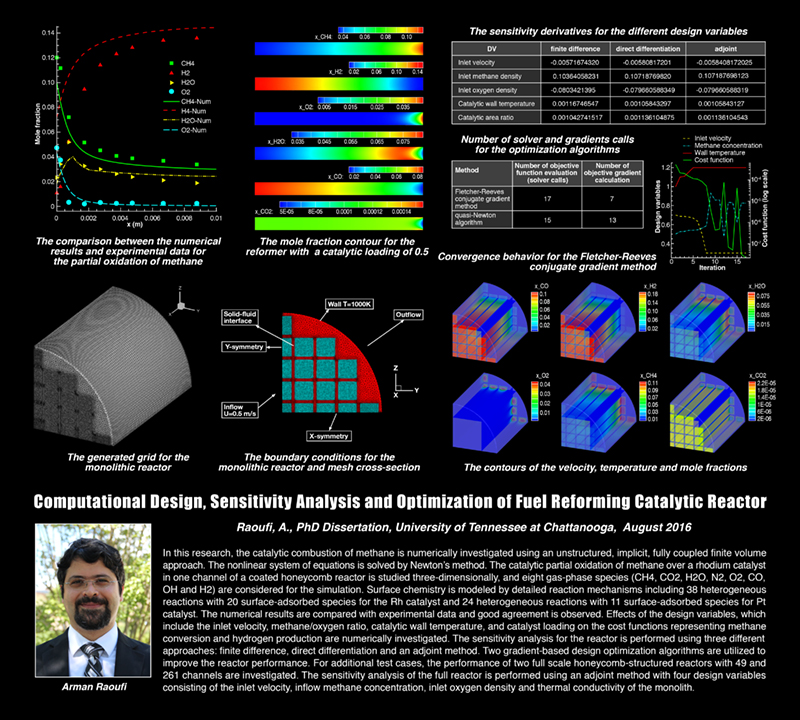

Computational Design, Sensitivity Analysis and Optimization of Fuel Reforming Catalytic Reactor

A Dissertation Presented for the Doctor of Philosophy in Computational Engineering, The University of Tennessee at Chattanooga

Arman Raoufi, August 2016

Abstract:

In this research, the catalytic combustion of methane is numerically investigated using an unstructured, implicit, fully coupled finite volume approach. The nonlinear system of equations is solved by Newton’s method. The catalytic partial oxidation of methane over a rhodium catalyst in one channel of a coated honeycomb reactor is studied three-dimensionally, and eight gas-phase species (CH4, CO2, H2O, N2, O2, CO, OH and H2) are considered for the simulation. Surface chemistry is modeled by detailed reaction mechanisms including 38 heterogeneous reactions with 20 surface-adsorbed species for the Rh catalyst and 24 heterogeneous reactions with 11 surface-adsorbed species for Pt catalyst. The numerical results are compared with experimental data and good agreement is observed. Effects of the design variables, which include the inlet velocity, methane/oxygen ratio, catalytic wall temperature, and catalyst loading on the cost functions representing methane conversion and hydrogen production are numerically investigated. The sensitivity analysis for the reactor is performed using three different approaches: finite difference, direct differentiation and an adjoint method. Two gradient-based design optimization algorithms are utilized to improve the reactor performance. For additional test cases, the performance of two full scale honeycomb-structured reactors with 49 and 261 channels are investigated. The sensitivity analysis of the full reactor is performed using an adjoint method with four design variables consisting of the inlet velocity, inflow methane concentration, inlet oxygen density and thermal conductivity of the monolith.

Click here to access a copy of Arman's dissertation.